Part 1: Manual or Standard Transmissions

September 1, 2010 | in Defensive Driving TipsWhat is a transmission?

The transmission transfers power from the engine to the wheels. Basically, by using gears and a device called a clutch, the transmission converts the spinning energy of the engine into torque, expressed as the force exerted on the road by the tires.

You need a transmission in part because every engine has a redline point–it can only spin so fast (so many RPMs) before it explodes. You’ll see the redline point marked on the RPM gauge on your dashboard. At the same time, there is a fairly narrow range of RPMs at which the engine is producing the maximum amount of power. A transmission consists of primarily gears, which can be used to convert a single input speed into an array of output speeds. As a result, your engine can continue operating near its optimal RPM while the car moves at different speeds. Your transmission also makes it possible for you to move in reverse as well as in forward without actually having to change the direction that the engine is spinning.

There are several kinds of transmissions: manual, automatic, and continuously variable transmissions (CVTs), as well as variations on these like the manumatic and semi-automatic transmissions. Most cars in the US these days have automatic transmissions, although many people still choose to drive a manual transmission. In many other countries, including much of Europe, Africa, and South America, manual transmissions are far more common, however.

In a manual transmission, the driver manually selects different gear ratios as he or she speeds up and slows down. Manual transmission vehicles have a third pedal, called the clutch pedal, which is used to activate the clutch (more on this later) in order to change gears. The average car will have five different gear ratios, as well as a reverse gear, although some older cars have fewer gear ratios and some high performance cars have more.

An automatic transmission uses a device called a planetary gear set, combined with a torque converter, to shift gears as the driver accelerates and decelerates, without any input from the driver herself. (There is also such a thing as a manual-style transmission that is controlled by a computer, rather than by the driver; this is known as an automated transmission.)

A continuously variable transmission has an almost endless array of gear ratios. CVTs used to be expensive and unreliable and so weren’t used often. However, the technology has improved, and now CVTs are appearing in more and more cars. For example, the popular hybrid Toyota Prius uses a CVT.

Manual and automatic transmissions each have their pros and cons; I’ll discuss these in the following post, which will deal with learning to drive a manual shift car. For now, I’m going to focus on the workings of a manual transmission. First, this is a simpler system to understand, as the same basic principles are used in an automatic transmission. Second, understanding how this system works will help you to learn to drive a manual transmission, if you don’t already know how to. If you do drive “stick” or “standard,” learning about the inner workings of your transmission could help you to be a more efficient driver and increase the life of your transmission.

Manual transmission–the basics

A transmission has input and output shafts. The input shaft is connected directly to the engine by the clutch; this shaft thus turns at the same RPM as the engine. The clutch, however, allows the driver to disconnect the engine from the transmission, which is necessary in order to change gears.

I’m going to start by describing a very basic two-speed transmission. Once you’ve grasped the basic principles through this simple model, it will be easier to understand the more complex workings of the typical five-speed transmission.

First, the transmission is connected to the engine by the clutch. A clutch is a device that lets you disconnect the engine from the transmission. When you push in the clutch pedal (the third pedal on a manual transmission vehicle), the engine will be running but the car won’t be moving. In the diagram below, the green shaft and gear are connected to the clutch. When the clutch pedal is released, this gear will spin at the same speed as the engine.

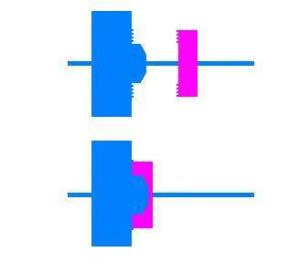

Figure 1: two-speed transmission diagram

The red shaft is called the layshaft. The red gears are connected to the shaft, so that the whole unit spins together. The green gear engages with the red gear on the layshaft; as a result, when the clutch is released, the layshaft spins together with the engine.

The blue shaft is connected directly to the drive shaft (through a device called a differential, which I’ll discuss in a different entry.) If the wheels are spinning, then the blue shaft will be spinning. Now, here is a key point. The blue gears–unlike the red and green gears–aren’t locked onto the blue shaft. Instead, they spin on bearings. For this reason, the blue shaft can turn inside these gears without actually turning the blue gears.

This is important because, as you’ll notice, the blue gears are meshed together with the red gears. If the blue gears were locked onto the blue shaft, then you wouldn’t be able to coast with the engine off or roll your car when it breaks down, because the drive shaft would turn the engine crankshaft when it moved.

There is, however, another component: the collar. This is the purple device on the blue shaft. The collar IS fixed to the blue shaft; you’ll also notice that the collar has teeth, as do the blue gears. When you move the gear selector fork, you slide the collar right or left, until it meshes with one of the blue gears. Once collar and gear mesh, then that gear starts to turn the blue shaft, and, by extension, the drive shaft.

So how does this allow you to get different output speeds from the same input? You’ll notice that the gears on the red and blue shafts are different sizes. When the smallest red gear turns once, it will only turn the bigger blue gear a fraction of a rotation. Thus, you’re turning higher input RPM into a lower output RPM when the collar engages the larger blue gear. When the bigger red gear engages the smaller blue gear, you’re producing more than one rotation in the blue gear for every rotation of the red gear. This results in a higher output speed. (This is called overdrive, which I’ll explain when I discuss a standard five-speed transmission.)

As you can see from this diagram, a small motion of the stick shift inside the car will shift the collar left or right, engaging a different gear. This is the basic principle behind an automatic transmission.

The Five Speed Transmission

Most cars, however, need more than just two gear ratios. Here is an updated version of the diagram above, with more gears added, to reflect a typical five-speed transmission:

Figure 2: five speed transmission

The basic principles and parts– gear ratios, collar, layshaft, gear selector fork, etc.–are the same. Here, however, you have three collars instead of one and six red and blue gears, instead of two. These correspond to the five gears labeled on a stick shift (first, second, third, etc.) and a reverse gear.

When you shift from first to second, you move the first collar from left to right. When you shift from second to third, however, you are pulling the first collar to the left and sliding the second collar to the right–so a single move of the stick shift actually produces two motions in the gear selector forks.

This is possible because, in a five speed transmission, there are THREE rods, each connected to one of the collars, that are ALL engaged by the stick shift lever. If you’ve driven a manual transmission, you’ll be familiar with the different positions of the shift lever, each of which corresponds to a different gear ratio:

Figure 3: shift lever positions

The red circle marks the shift lever. When it is in the central “pivot” point, as shown here, then none of the blue gears are engaged, and the car is in neutral. To shift into first gear, the lever is moved to the left and up, along the lines shown.

As you can see from this diagram, there are three vertical axes: first-second, third-fourth, and fifth-reverse. Each of the axes corresponds to a different shift rod, which is in turn connected to one of the three collars. Do you see how this makes sense? You use the same rod to shift between first and second (i.e. same collar), so you move the shift lever from “top” to “bottom” on the diagram, which in turn moves this collar from left to right.

When you shift from second to third, you move the shift lever from bottom to top and from left to right, through the pivot point in the center. This allows you to shift one collar to the right and the other to the left. Notice that the shift rods move in the direction opposite to the motion of the shit lever itself. See Figure 4 below.

Figure 4: shifting rods

Reverse Gear

What about reverse gear? As you can see in Figure 2, the reverse gear is slightly different from the other gears. Instead of the blue gear meshing directly with the red gear, these two gears are separated by a third gear, called the idler, which reverses the direction of rotation.

When a gear turns, its teeth push against the teeth of the meshed gear, turning this gear in the opposite direction. If the red gears are turning counter-clockwise, then the blue gears will be turning clockwise. However, in the case of the reverse gear, the idler gear will be turning clockwise; the blue gear will then be turning counter-clockwise, in the opposite direction from the other blue gears (remember this is possible because none of the blue gears are fixed to the blue shaft.)

Overdrive

Take a look at figure 2 again. As you’ll see, in a five-speed transmission like this one, only one of the red gears is larger than the corresponding blue gear. This gear ratio corresponds to fifth gear, which is also known as an “overdrive” gear. When selected, the output speed will be higher than the input speed. As a result, this gear is generally used for highway cruising at high speeds. Under these conditions, this gear ratio will improve fuel efficiency and often allow for quieter engine operation. The fifth gear is generally best engaged at speeds over 45 mph.

Synchronizers

Now, you may have already noticed a potential problem with this system. The blue shaft (and the collars) spin at one speed, while the blue gears spin at different speeds. Thus, the speed of the collar and the speed of a blue gear may not match. How, then, can you get the “teeth” on the collar to fit into the teeth on the gear? When these don’t fit together properly, you’ll hear a nasty grinding noise (which you’ll likely be familiar with if you drive a standard transmission.)

In older cars (and in some modern race cars), drivers had to use a technique called “double clutching” to avoid this problem. When a driver wanted to change gears, he would first engage the clutch and shift into neutral, so that the collars weren’t engaging any gears. He would then rev the engine until the RPM of the engine reached the right speed: the speed at which the desired output (blue) gear would be spinning at the same speed as the wheels–and hence the same speed as the collar. He could then lock the collar and blue gear together.

This of course makes driving more of a fine art than a basic skill. I’ve been driving standard for years, and the thought of double clutching still makes me quail. Luckily, in 1952, Porsche developed a simple yet elegant solution for this problem: the synchronizer (see Figure 5).

Figure 5: synchronizer

The synchronizer (or “synchro”) is a small cone on the outside of each blue gear. The collars have a corresponding hollow–a negative version of the synchro. As the collar is brought towards the blue gear, the cone and the hollow make contact first. Since these parts just fit together, the friction between them causes the collar and the blue gear to spin at the same speed BEFORE the teeth actually lock the two together. Shifting suddenly becomes much, much simpler!

Most cars have synchronizers on all gears except for the reverse gear. For this reason, you generally have to bring the car to a full stop before shifting into reverse. (Otherwise, you’ll hear that dreaded teeth-grinding noise!) However, some manufacturers–Lamborgini and BMW, among others–do use synchros on the reverse gear.

The Clutch

The clutch is the devise used to connect and disconnect the engine from the transmission. On manual transmission cars, the clutch is operated by a pedal. When the clutch pedal is fully depressed, the engine is disengaged from the transmission. When the clutch pedal is fully released, the engine is fully engaged, i.e. is transferring all of its torque (power) to the transmission.

The clutch has three main components: the flywheel, the clutch disc, and the pressure plate.

The flywheel is a large steel or aluminum disc connected to the crankshaft. It helps to dampen engine vibrations, as well as serving as the base for the clutch.

The clutch plate is a second disc covered with a material that will create friction when in contact with the flywheel. The clutch plate is connected to the transmission input shaft. When the clutch pedal is released, the clutch disc is pressed against the flywheel, so that flywheel and clutch plate spin together.

The pressure plate sits on the other side of the clutch plate; it’s basically a spring-loaded friction surface. These springs push the pressure plate into the clutch plate. When the clutch pedal is released, the clamping force of the springs is activated; the opposite happens when the pedal is engaged.

The whole system is contained in the clutch housing.

Because the plates engage one another by friction, this isn’t a simple “on/off” system; as the pedal is being depressed or released, the clutch plate engages partially and slips partially. This “slipping” is what allows the driver to start the car from a standstill or change gears while in motion, as it allows the rotation speeds of engine and transmission to gradually come into alignment. Learning to properly deploy the clutch in order to accomplish this, however, can be a bit difficult for new drivers to master.

Now that you know the theory behind how a manual transmission works, I’ll discuss the practice of actually driving a standard shift car in my next entry!

To learn more about this topic, or a broad range of subjects from “How To Change A Tire” to “How To Jumpstart Your Car”, visit DefensiveDriving.com’s Safe Driver Resources website!

Visit our state-specific sites for more information about online defensive driving in Texas, California, Florida, and New Jersey.

← Don’t talk to me about work – how would you answer these questions? | Florida Traffic School: Which Course To Take? →